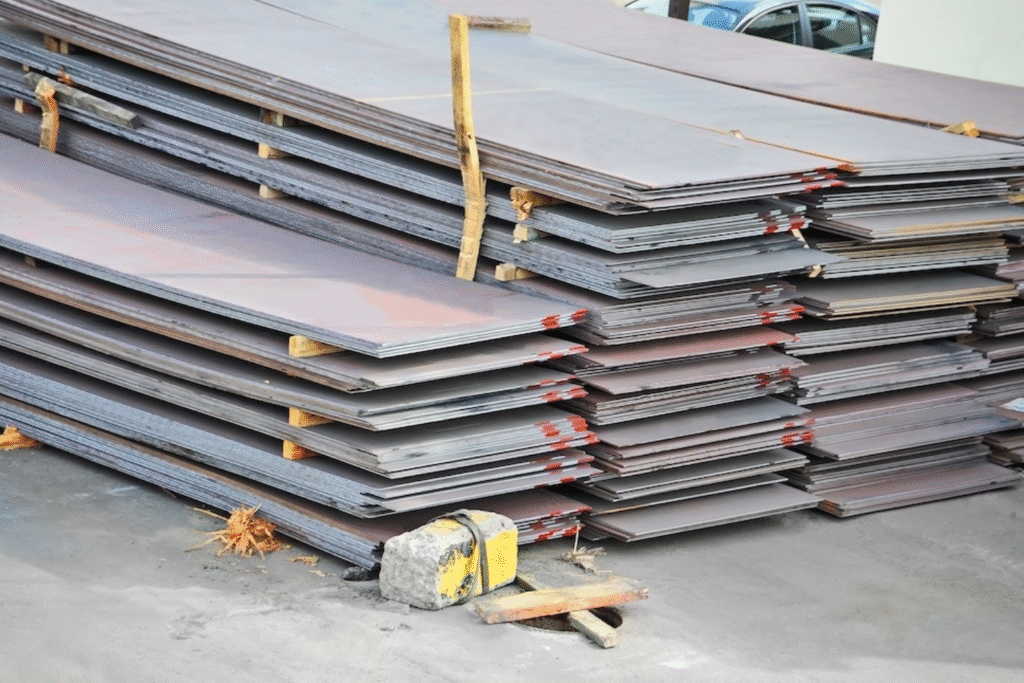

Walk into any aerospace hangar, chemical processing plant, or bridge construction site, and you’ll likely find one common denominator: precision-cut metal stock ready to shape the backbone of a high-performance system. While industry headlines tend to spotlight innovation in alloys and automation, the real foundation often starts with something much simpler—bar and plate materials.

These foundational building blocks are not flashy, but they are essential. Behind every industrial breakthrough is a trusted supply of raw materials ready to be turned into high-performance parts. Let’s explore why Bar & Plate products remain indispensable to industries that rely on strength, consistency, and adaptability.

The Unsung Role of Raw Metal Stock

In engineering circles, raw material form matters just as much as its grade. Plates and bars aren’t just metal—they’re starting points. Their dimensional stability and machinability make them ideal for components that demand tight tolerances, uniformity, and reliable mechanical properties.

- Round Bars get turned into shafts, fasteners, flanges, and valve components.

- Flat Bars find their way into structural supports, custom brackets, and fabricated assemblies.

- Plates form the backbone of pressure vessels, base frames, and reinforcement panels.

Because these materials are fully solid, they offer consistent metallurgical properties throughout their cross-section, making them ideal for high-stress and high-temperature applications.

Precision Starts With the Right Cut

What sets suppliers apart isn’t just what they carry—it’s how they prepare it.

At James Duva Inc., bar and plate materials aren’t pulled from a shelf and shipped blindly. They’re cut to spec, in-house, and handled by a team that understands how even a half-inch of tolerance can make or break a project’s success. Whether it’s a nickel alloy for corrosion resistance or a duplex stainless for strength in marine conditions, customization matters.

With access to a broad range of grades—304, 316, 2205, Alloy 20, Inconel, and more—Duva ensures that clients in chemical, food, energy, and pharma sectors don’t just get material—they get fit-for-purpose material.

From Supply Chain to Lifeline

In a time of fluctuating material availability and tight project timelines, having a reliable metal supplier is no longer optional—it’s critical. Delays in sourcing bar and plate stock can stall production lines, delay project handoffs, and cascade into missed contracts.

James Duva Inc. has built its reputation not just on inventory depth, but on a process-driven approach to sourcing, cutting, and delivering bar and plate products with precision and accountability.

Why It’s Time to Rethink the Basics

Engineers and procurement teams often focus on innovation at the surface—new processes, digital design, automation. But in the background, none of that works without a foundation of dependable material.

By working with a trusted supplier for Bar & Plate materials, manufacturers unlock more than raw stock—they gain a partner who understands the demands of industrial execution, material science, and application performance.

Conclusion

Bar and plate metals may not steal headlines, but they anchor some of the most complex, high-pressure projects in modern industry. From the strength of a bridge beam to the corrosion resistance of a chemical tank, these materials shape outcomes before the first weld is even made.

And in a world that runs on precision, strength, and timeliness—those are things worth paying attention to.