Discover how to boost efficiency in your industry with the Type E thermocouple. Learn key strategies and benefits for optimal performance.

In the ever-evolving industrial landscape, precision and reliability play pivotal roles in optimizing processes and ensuring efficiency. The choice of the right thermocouple can significantly impact these aspects, making the Type E thermocouple a standout option due to its unique characteristics and applications. How can industries best leverage the advantages of the Type E thermocouple to enhance performance and outcomes?

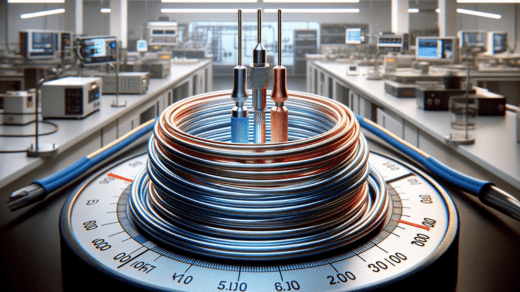

Understanding Type E Thermocouples

Type E thermocouples are highly regarded for their exceptional accuracy and stability, making them a popular choice in industries that demand precise temperature measurement. Comprising Chromel (nickel-chromium alloy) and Constantan (copper-nickel alloy), E Type thermocouples offer a wide temperature range (-200°C to 900°C) and excellent sensitivity. The positive leg (Chromel) and negative leg (Constantan) generate a voltage output proportional to the temperature disparity between the measurement point and the reference junction.

Functionality of Type E Thermocouples

Type E thermocouples produce a millivolt signal when subjected to a temperature gradient, based on the Seebeck effect. This effect generates a voltage due to the temperature difference between the two junctions, which is then converted into precise temperature readings by a connected instrument or controller, enabling accurate monitoring and control of industrial processes.

Advantages of Type E Thermocouples

- High Accuracy: Type E thermocouples offer remarkable precision levels, making them ideal for applications requiring accurate temperature control.

- Fast Response Times: Their small diameter and high sensitivity enable Type E thermocouples to swiftly respond to temperature changes, facilitating real-time adjustments in industrial processes.

- Wide Temperature Range: Type E thermocouples find utility in various industrial environments, from cryogenic to high-temperature applications, owing to their extensive temperature range.

Applications of Thermocouples Type E in Industry

Type E thermocouples are extensively employed in food processing, pharmaceuticals, petrochemicals, and HVAC systems due to their superior accuracy and reliability, making them ideal for various applications:

Food Processing

In food processing, a thermocouple Type E is essential for maintaining precise temperatures during cooking, cooling, and storage. They are commonly utilized in ovens, refrigeration units, and pasteurization equipment to accurately monitor and control temperature variations.

Pharmaceuticals

The pharmaceutical industry relies on stringent temperature control to preserve medication and vaccine efficacy. Type E thermocouples play a vital role in monitoring temperature-sensitive processes like sterilization, lyophilization, and storage in pharmaceutical manufacturing.

Petrochemicals

In petrochemical plants with high temperatures and corrosive environments, Type E thermocouples provide accurate temperature measurements for processes such as distillation and furnace operations. Their durability and reliability make them a preferred choice for critical applications in the petrochemical industry.

HVAC Systems

HVAC systems necessitate precise temperature monitoring to maintain indoor comfort and energy efficiency. Type E thermocouples regulate heating and cooling processes in HVAC equipment, ensuring optimal performance and occupant comfort in commercial and residential buildings.

Tips for Maximizing Efficiency with Type E Thermocouples

To optimize the efficiency and lifespan of Type E thermocouples in industrial settings, consider the following tips:

Regular Calibration

Regular calibration of Type E thermocouples is crucial to maintain accuracy and ensure reliable temperature measurements. Calibration against a known reference temperature source helps identify any drift or inaccuracies, allowing for timely adjustments and corrections.

Proper Installation

Ensure the proper installation of Type E thermocouples to minimize signal interference and ensure accurate temperature readings. Securely attach the thermocouple probes to the measurement points, avoiding strain or bending that could impact the signal output.

Insulation and Protection

Protect Type E thermocouples from environmental factors such as moisture, vibration, and contaminants that can affect performance. Use suitable insulation materials and protective sheaths to shield the thermocouple wires and probes from external influences, prolonging their lifespan and accuracy.

Comparison of Type E Thermocouples with Other Types

When selecting thermocouples for industrial applications, consider specific process and environmental requirements. Here’s a comparison of Type E thermocouples with other common types:Comparison Type E Thermocouples Type K Thermocouples Type J Thermocouples Temperature Range -200°C to 900°C -200°C to 1260°C -40°C to 750°C Accuracy High accuracy levels Suitable for precise applications Preferred for high-accuracy applications Sensitivity High sensitivity Lower sensitivity Suitable for moderate temperature ranges Comparison Type E Thermocouples Type K Thermocouples Type J Thermocouples Temperature Range -200°C to 900°C -200°C to 1260°C -40°C to 750°C Accuracy High accuracy levels Suitable for precise applications Preferred for high-accuracy applications Sensitivity High sensitivity Lower sensitivity Suitable for moderate temperature ranges

Troubleshooting Type E Thermocouples

Despite their reliability, Type E thermocouples may encounter issues that impact their performance. Here are some common problems and troubleshooting tips:

Drift in Readings

If the temperature readings from the Type E thermocouple exhibit drift or inconsistency, check for loose connections, damaged wires, or a faulty instrument. Ensure all connections are secure and clean, and recalibrate the thermocouple if necessary to correct inaccuracies.

Signal Interference

Electromagnetic fields or nearby equipment can disrupt the signal output of Type E thermocouples. Keep the thermocouple wires away from sources of interference and use shielded cables if needed to minimize signal distortion.

Insulation Degradation

Regularly inspect the insulation around the thermocouple wires, as it may degrade over time due to exposure to heat, chemicals, or mechanical stress. Replace any damaged or worn-out sections to prevent signal loss or inaccurate readings.

By comprehending the principles of operation, applications, maintenance tips, and troubleshooting strategies for Type E thermocouples, industrial facilities can harness the full potential of these reliable temperature sensors to optimize processes, enhance efficiency, and ensure product quality. Thoughtfully integrating Type E thermocouples into industrial systems can lead to improved performance and long-term cost savings in manufacturing and processing industries.