Are you familiar with drag reducers? These incredible additives are transforming the way fluids are transported, enhancing efficiency and reducing energy consumption. Whether it’s oil pipelines, water distribution systems, or industrial processes, drag reducers play a vital role in optimizing fluid flow.

In this blog post, we will dive deep into the world of drag reducers. We’ll explore what they are, their different types and applications, and how they can benefit various industries. So get ready to unveil the secrets behind these game-changing substances that have cemented their place as essential tools for fluid transportation optimization!

What are Drag Reducers?

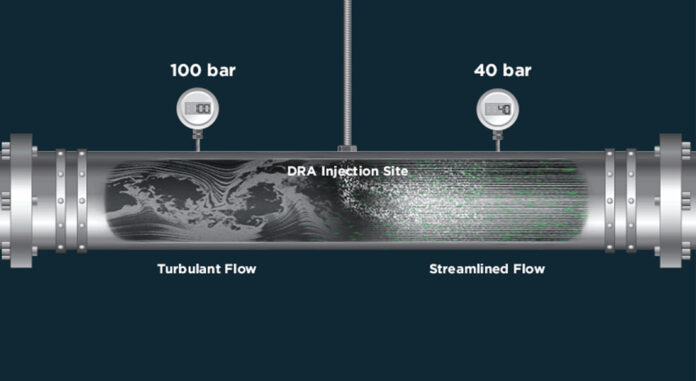

Drag reducers, also known as drag reducing agents or flow improvers, are chemical additives designed to reduce the resistance of a fluid flowing through a pipeline. They work by modifying the turbulent boundary layer of the fluid, effectively decreasing friction and drag forces. This allows for increased flow rates and reduced pressure drops.

These remarkable substances come in various forms, including polymers, surfactants, and nanoparticles. Each type offers unique properties that cater to different applications. Polymers such as polyacrylamides are commonly used in oil pipelines and water distribution systems due to their excellent drag reduction capabilities.

Surfactant-based drag reducers are ideal for enhancing fluid transport efficiency in industrial processes like mining or wastewater treatment. These compounds alter the surface tension between the fluid and pipe walls, leading to reduced turbulence and improved overall flow performance.

In recent years, advancements in nanotechnology have led to the development of nanoparticle-based drag reducers. These tiny particles can be dispersed within fluids to minimize frictional losses during transportation across long distances.

No matter which type is employed, drag reducers offer numerous benefits beyond simply reducing energy consumption. They enhance pipeline capacity by allowing higher flow rates without compromising system integrity or requiring expensive infrastructure upgrades. Additionally, they decrease maintenance costs associated with wear-and-tear on pipes caused by high-velocity flows.

The versatility of drag reducers extends far beyond traditional industries too – they have found application in sectors like chemicals manufacturing, food processing plants, and even fire suppression systems! With their ability to optimize fluid transportation across diverse fields, it’s no wonder that these additives have become indispensable tools for improving operational efficiency worldwide.

Types of Drag Reducers and Their Applications

Drag reducers, also known as flow improvers or drag-reducing agents, are chemical additives that have the ability to reduce frictional resistance in fluid flow. They are widely used in various industries such as oil and gas, water treatment, and transportation.

One type of drag reducer is polymer-based. These polymers work by altering the rheological properties of the fluid, reducing turbulence and increasing laminar flow. Polymer-based drag reducers are commonly used in pipeline systems to enhance the efficiency of fluid transport.

Another type is surfactant-based drag reducers. Surfactants lower surface tension between liquid molecules, allowing for smoother flow through pipelines. They are often used in applications where high shear rates occur, such as crude oil transportation.

Silicone-based drag reducers offer excellent stability under extreme conditions like high temperatures and pressures. They find applications in hydraulic fracturing operations where they help improve productivity by reducing pumping pressure requirements.

In addition to these types, there are also hybrid drag reducers that combine different technologies to achieve optimal performance in specific applications.

The selection of a particular type of drag reducer depends on factors such as the nature of the flowing medium, desired efficiency improvement targets, operating conditions (temperature and pressure), compatibility with other additives present in the system, and cost considerations.

Conclusion

In today’s fast-paced world, efficiency and productivity are key factors in any industry. When it comes to reducing drag and optimizing performance, drag reducers play a crucial role. These innovative chemicals have the power to transform operations across various sectors.

From oil and gas pipelines to wastewater treatment plants, drag reducers have proven their worth time and time again. By effectively minimizing friction, these additives enable smoother flow rates, reduced energy consumption, and increased operational efficiency.

Whether you’re a cementing additives manufacturer or a supplier in the industry, incorporating drag reducers into your product lineup can be a game-changer. The benefits of utilizing these powerful solutions are clear – enhanced performance, cost savings, improved environmental sustainability – all leading to greater success for your business.

To fully unleash the power of drag reducers, it is important to understand the different types available and their specific applications. Each sector has its own unique requirements and challenges that can be addressed with tailored solutions. Consulting with experts in the field will ensure that you choose the right type of drag reducer for your specific needs.

As technology continues to advance, so too does our understanding of how chemical additives can optimize industrial processes. Drag reducers represent just one piece of this puzzle but offer immense potential for improving overall efficiency.

So if you’re looking for ways to boost productivity while reducing costs within your industry, don’t overlook the power of drag reducers. Embrace innovation and stay ahead of the curve by incorporating these cutting-edge solutions into your operations.