Introduction to Precious Metal Refining

Long ago, people believed in alchemy, a practice that aimed to turn raw metals into gold. While they never found the secret to making gold from other metals, their experiments laid the groundwork for the modern metal refining process.

If you also wonder how ordinary metals become so valuable and beautiful, let us walk you through the process of precious metal refining and how MasterMelt Group aims to make it more sustainable for the environment.

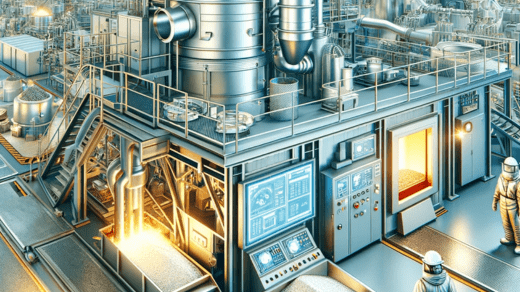

The Precious Metal Refining Process

The process of refining precious metals is explained below:

1. Collection and Sorting of Raw Materials

Precious metal refining begins with collecting and sorting raw materials from various sources. These sources can be old jewelry, discarded electronic devices, and industrial by-products. At MasterMelt, we systematically sort these materials to identify and separate precious metal-containing components. This helps us carry out the job with utmost precision.

2. Testing for Precise Metal Content

Once the raw materials are sorted, they undergo rigorous testing. This crucial step determines the exact composition of precious metals, ensuring accurate valuation and efficient refining. This testing process is majorly carried out using the following metallurgical methods –

● Pyrometallurgy

Pyrometallurgy involves separating precious metals from unwanted elements by using high temperatures.

● Hydrometallurgy

Hydrometallurgy relies on chemical solutions to isolate and dissolve precious metals from its source.

MasterMelt Group’s Commitment to Sustainability

At MasterMelt Group, sustainability is ingrained in our core values. Our dedication reflects our efforts to review and improve our environmental and social performance.

Our strategy is built on 4 pillars, each contributing to a lasting, positive impact:

1. Sustainable Circular Economy

Our aim is to be a company where materials are reused and recycled to minimize waste and conserve resources.

2. Responsible Material Sourcing

We source materials only from responsible sources. Our automated customer and material screening process also ensures we intake post-industrial and post-consumer waste materials.

3. Environmental Health and Safety Excellence

Our focus is on implementing best practices to ensure the safety of our employees and the communities we operate in.

4. Greenhouse Gas Emissions and Energy Reduction

We are committed to bringing in more energy-efficient equipment and changing our operational practices as needed.

Advantages of Precious Metal Refining

Some of the advantages of precious metal refining are as follows:

1. Turning Trash into Treasure

Precious metal refining helps turn old and discarded items into valuable assets. This best out-of-waste approach promotes recycling.

2. Saving Money for Businesses

Refining precious metals allows businesses to recover valuable metals from waste. This further results in promoting their ROI.

3. Protecting the Environment

Precious metal refining reduces the need for mining these metals. This further contributes to conserving natural resources and minimizing the environmental impact.

Industries Utilizing Refined Precious Metals

The refined precious metals find applications in various industries like:

1. Jewelry Industry

The jewelry industry extensively uses refined precious metals to create stunning and valuable ornaments.

2. Electronics Industry

Refined precious metals, such as gold and silver, are essential in electronics. They are used for manufacturing connectors and other components, considering their excellent conductivity and reliability.

3. Pharmaceutical Industry

The pharmaceutical industry uses refined precious metals as catalysts in certain drug manufacturing processes. They enable more efficient and precise chemical reactions for producing medications and pharma compounds.

Ensuring Quality and Certifications

Maintaining high standards in the refining process is of utmost importance. Mastermelt takes great pride in providing the highest quality standards and maintaining the necessary certifications to uphold our commitment to excellence.

Some of our accreditations highlighting our quality and sustainability include:

- ISO 9001:2015 Quality Management FS 31974

This accreditation certifies that Mastermelt adheres to stringent quality management systems, ensuring consistency and excellence in our operations.

- ISO 14001:2015 Environmental EMS 504582

This certification reflects our commitment to environmental management and sustainability, demonstrating our efforts to reduce our ecological impact.

Conclusion

The precious metal refining process is vital in turning discarded materials into valuable assets. This process benefits numerous industries and contributes to environmental sustainability by reducing waste and promoting recycling. So, take your first step toward sustainability with MasterMelt. With over 35 years of experience and a financially secure foundation, we are committed to responsible refining practices.